The Mechanics of Internal Combustion Engines

Internal combustion engines (ICEs) have been a cornerstone of transport for over a century, powering a vast array of vehicles from everyday cars to heavy-duty trucks and motorcycles. Understanding how these intricate machines convert fuel into motion is fundamental to appreciating modern automotive engineering. This article delves into the core principles, key components, and operational cycles that define the internal combustion engine, exploring its foundational role in vehicle mobility and its ongoing evolution within the broader landscape of propulsion technologies.

The internal combustion engine, often simply called an ICE, operates on a principle of controlled explosions within a confined space to generate mechanical energy. This energy is then harnessed to propel a vehicle. At its heart, an ICE takes a mixture of fuel and air, ignites it, and uses the resulting expansion of gases to push a piston, initiating a chain reaction that ultimately turns the vehicle’s wheels. This process, typically a four-stroke cycle, underpins much of our global transport infrastructure, from personal cars to large-scale industrial vehicles, defining the experience of driving for millions.

Understanding the Core Principles of Internal Combustion

At its most basic, an internal combustion engine works by burning fuel inside a combustion chamber. This combustion creates high-pressure gas that exerts force on moving components. The most common configuration involves pistons moving within cylinders. The four strokes—intake, compression, power (combustion), and exhaust—describe the piston’s journey and the valve actions required to draw in air and fuel, compress it, ignite it, and expel the spent gases. This continuous cycle is what transforms the chemical energy stored in fuel into the kinetic energy needed for mobility.

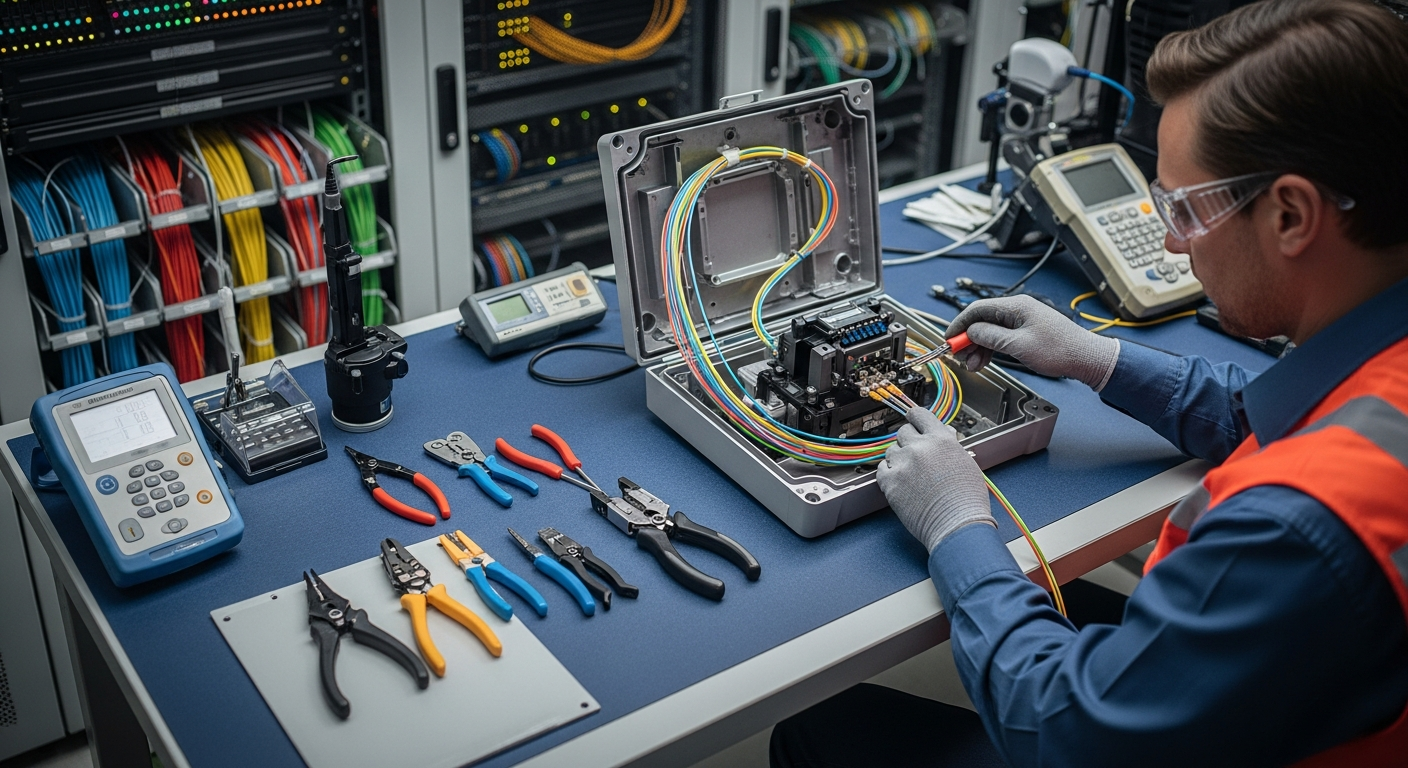

Key Components and Their Interplay in Automotive Design

Several critical components work in synchronicity to achieve engine performance. The cylinder block houses the cylinders and pistons. Connecting rods link the pistons to the crankshaft, which converts the pistons’ linear motion into rotational motion. The cylinder head, located above the cylinders, contains the valves (intake and exhaust) and spark plugs (in gasoline engines) or fuel injectors (in diesel engines). The camshaft controls the opening and closing of these valves, ensuring proper timing for each stroke. This intricate automotive design allows for precise control over the combustion process, crucial for both power and efficiency.

Fuel, Ignition, and Exhaust Systems in Engine Operation

For an engine to operate, it requires a carefully managed supply of fuel and air, a method to ignite the mixture, and a system to manage the byproducts of combustion. The fuel system delivers fuel from the tank to the engine, often via injectors. The ignition system, typically involving spark plugs and an ignition coil in gasoline engines, provides the spark to ignite the compressed fuel-air mixture. The exhaust system collects the spent gases from the cylinders and channels them away from the engine, often through catalytic converters that reduce harmful emissions before releasing them into the atmosphere. This technological orchestration ensures effective and relatively clean operation.

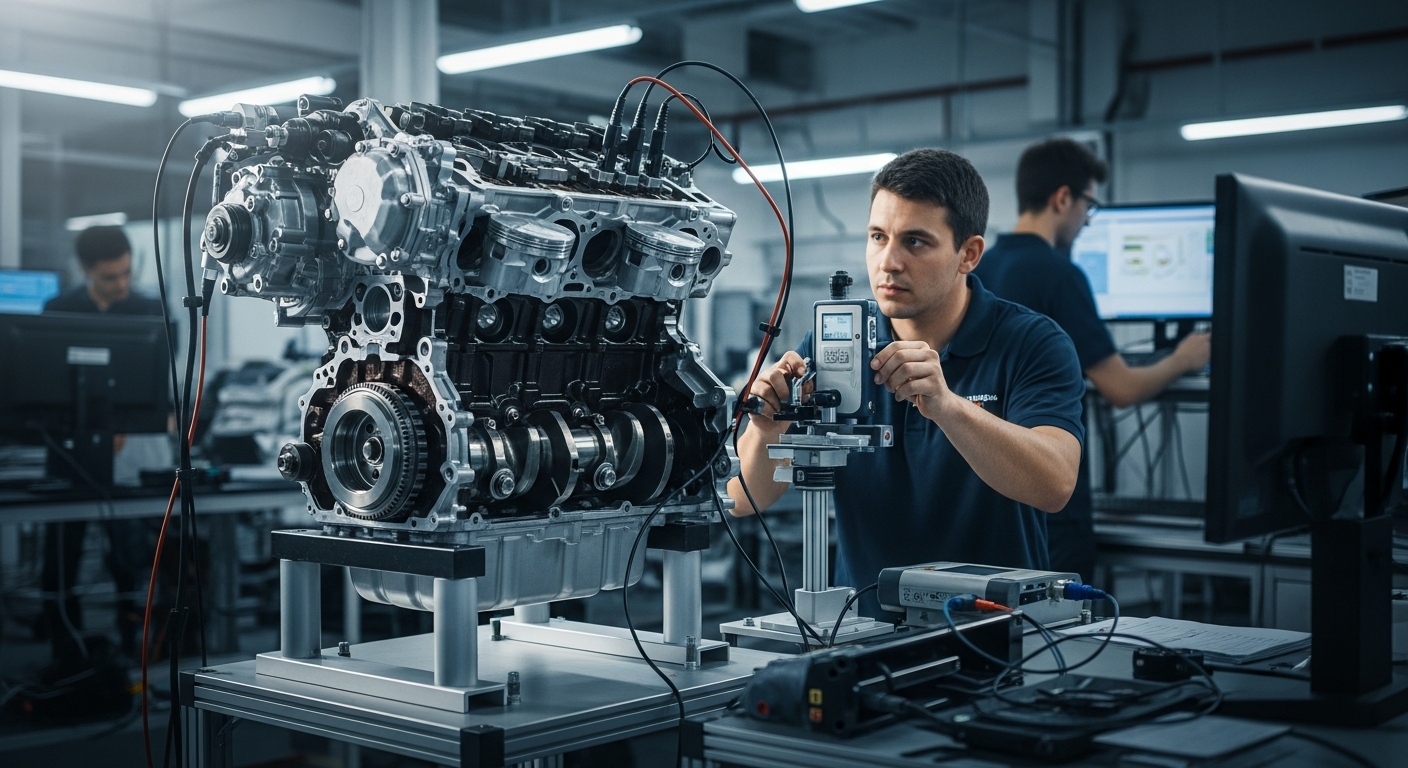

The Evolution and Innovation in Engine Technology

The internal combustion engine has undergone significant innovation since its inception. Early engines were simple and inefficient, but continuous advancements have led to remarkable improvements in power output, fuel efficiency, and emissions control. Modern engines incorporate technologies such as direct fuel injection, variable valve timing, turbocharging, and advanced electronic control units (ECUs). These developments have not only enhanced driving performance but also addressed environmental concerns, pushing the boundaries of what is possible with this established engine technology. The quest for greater efficiency and reduced environmental impact continues to drive research and development in this field.

Internal Combustion Engines in Modern Transport and Mobility

Internal combustion engines remain a dominant force in global transport, powering the vast majority of cars, trucks, and motorcycles on the road. Their versatility, relatively low cost of initial production, and established fueling infrastructure have cemented their role in personal and commercial mobility. However, the future of transport is also seeing a significant shift towards alternative power sources. Hybrid vehicles combine an ICE with an electric motor, offering improved fuel economy, while fully electric vehicles represent a move away from fossil fuels entirely. This evolving landscape highlights the ongoing transition in automotive technology, where ICEs continue to adapt and coexist with newer propulsion systems, influencing decisions about road travel and sustainable transport.

Internal combustion engines have fundamentally shaped the modern world, providing the power for countless vehicles that facilitate daily life and commerce. From their basic principles of converting fuel into motion to the sophisticated systems that manage ignition and exhaust, these engines represent a triumph of engineering. While the automotive industry continues to innovate with electric and hybrid technologies, understanding the mechanics of ICEs remains crucial to appreciating the history and ongoing evolution of transport and mobility.