Innovations in Automotive Powertrain Efficiency

The automotive industry is in a constant state of evolution, driven by the increasing global demand for more efficient and sustainable transport solutions. Innovations in powertrain technology are fundamentally reshaping this sector, focusing on reducing fuel consumption, lowering emissions, and significantly enhancing overall vehicle performance. This article delves into the diverse advancements that are defining the future of driving and mobility, encompassing everything from sophisticated electric and hybrid systems to refined internal combustion engines and cutting-edge engineering practices.

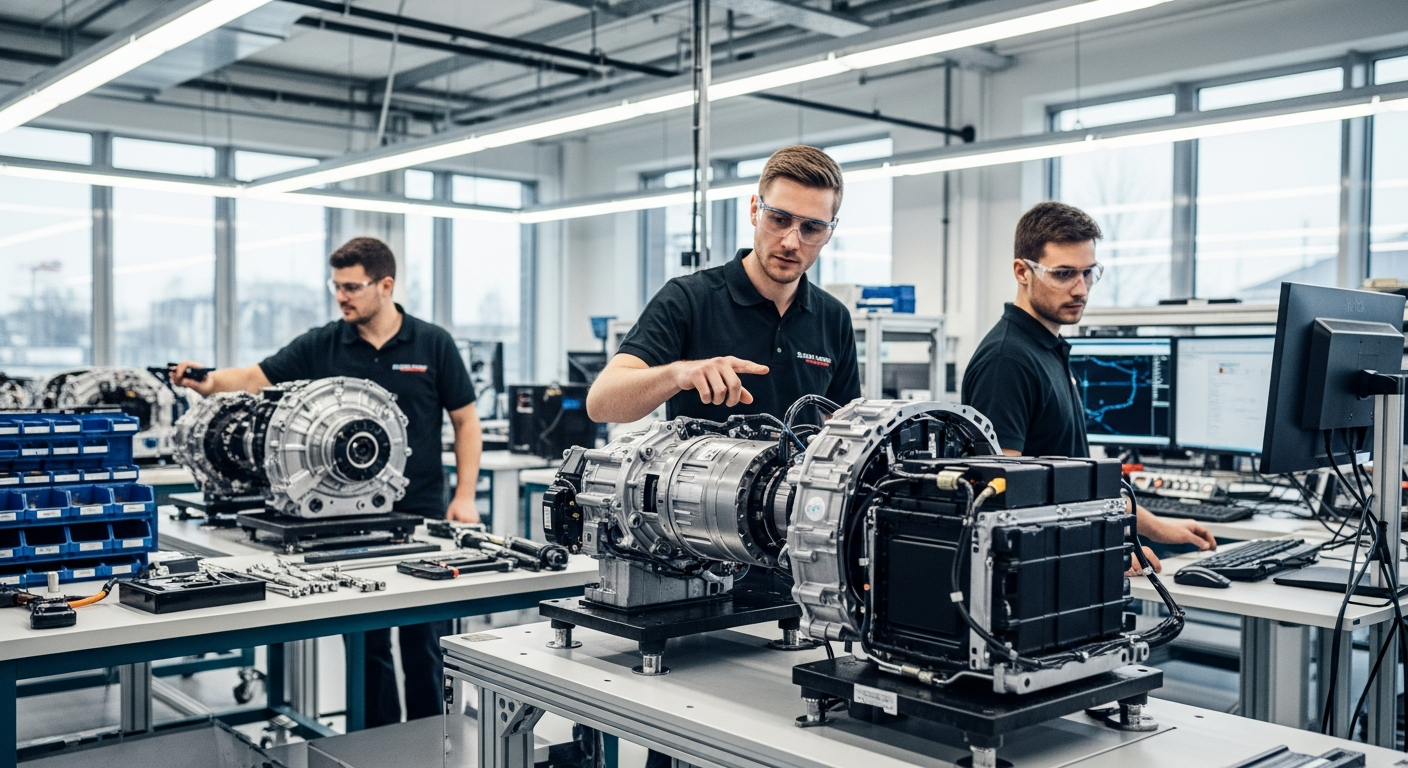

Evolution of Powertrain Engineering and Technology

The journey towards greater automotive efficiency is deeply rooted in continuous engineering and technological innovation. Historically, internal combustion engines (ICE) have undergone extensive refinement, transforming from rudimentary designs into highly sophisticated systems. Early innovations focused on basic power delivery, but modern engineering emphasizes precision fuel delivery, optimized air intake, and advanced exhaust gas treatment. This foundational shift has paved the way for the integration of complex electronic controls and the development of new materials, all contributing to more robust and efficient powertrain systems. The ongoing pursuit of innovation in this area is critical for both performance and environmental considerations, influencing every aspect of vehicle design and manufacturing.

Advancements in Electric and Hybrid Mobility Systems

The landscape of automotive mobility is being profoundly reshaped by the rapid advancements in electric and hybrid powertrain systems. Battery electric vehicles (BEVs) are at the forefront, offering zero tailpipe emissions and immediate torque, driven by improvements in battery energy density, charging speeds, and overall system integration. Hybrid electric vehicles (HEVs) and plug-in hybrid electric vehicles (PHEVs) offer a bridge, combining the benefits of electric propulsion with the range and flexibility of an ICE. Innovations in battery technology, power electronics, and regenerative braking systems are continuously extending electric range and enhancing the efficiency of both BEVs and hybrid models. These technologies represent a significant step towards a sustainable future for transport.

Enhancing Fuel Efficiency in Modern Vehicles

Despite the rise of electrification, internal combustion engines continue to benefit from significant innovations aimed at enhancing fuel efficiency. Modern ICE designs incorporate technologies such as direct fuel injection, turbocharging, and variable valve timing, which precisely manage fuel-air mixtures and combustion processes to maximize energy extraction while minimizing waste. Beyond the engine itself, the overall vehicle design plays a crucial role. The widespread adoption of lightweight materials, including high-strength steel, aluminum alloys, and advanced composites, significantly reduces vehicle mass, thereby requiring less energy for propulsion. Aerodynamic design principles are also meticulously applied to minimize air resistance, further contributing to improved fuel economy and overall driving performance.

The Role of Advanced Materials and Manufacturing

Advanced materials and sophisticated manufacturing processes are indispensable to the ongoing innovation in automotive powertrains. The drive for lighter, stronger, and more durable components has led to the development and integration of materials like carbon fiber reinforced polymers, magnesium alloys, and specialized ceramics. These materials not only reduce the overall weight of the vehicle, which directly impacts fuel efficiency and electric range, but also allow for the creation of more compact and high-performance powertrain components. Innovations in manufacturing, such as additive manufacturing (3D printing) and advanced casting techniques, enable the production of intricate designs with optimal material distribution, leading to more efficient and robust systems.

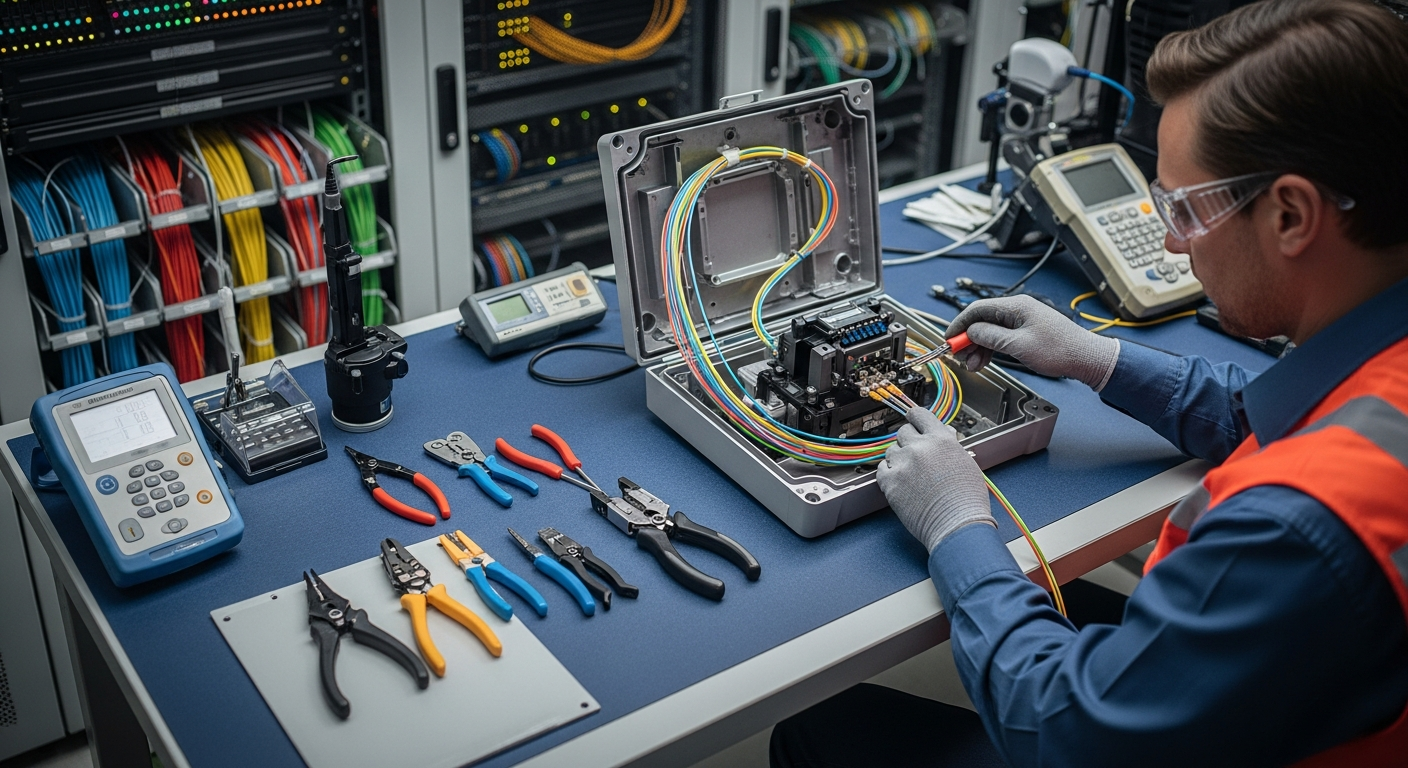

Software and Automation in Powertrain Management

The increasing complexity of modern powertrains, especially hybrid and electric systems, necessitates sophisticated software and automation for optimal management. Advanced electronic control units (ECUs) and integrated software platforms continuously monitor and adjust engine, transmission, and electric motor operations in real-time. This ensures peak performance and efficiency under varying driving conditions. Features like predictive energy management use navigation data to anticipate terrain and traffic, optimizing power delivery and regenerative braking. Automation in these systems also contributes to enhanced safety and a smoother driving experience, representing a critical intersection of technology and performance in contemporary vehicle design.

| Manufacturer | Key Powertrain Innovation Focus | Notable Technology |

|---|---|---|

| Toyota | Hybrid Electric Systems | Synergy Drive System (e.g., Prius, RAV4 Hybrid) |

| Tesla | Battery Electric Vehicles (BEVs) | Permanent Magnet Synchronous Reluctance Motors, Gigafactory Battery Production |

| Hyundai/Kia | Fuel Cell Electric Vehicles (FCEVs), Hybrid/EVs | NEXO Fuel Cell System, E-GMP Platform |

| Volkswagen | Modular Electric Drive Matrix (MEB) | MEB Platform for scalable EV production |

| General Motors | Ultium Battery Platform | Ultium Batteries and Drive Units for various EV segments |

Conclusion

The continuous flow of innovations in automotive powertrain efficiency underscores a profound transformation within the transport sector. From the intricate refinements of internal combustion engines to the widespread adoption of advanced electric and hybrid systems, each development contributes to a future where vehicles are more sustainable, performant, and environmentally responsible. The integration of cutting-edge engineering, advanced materials, and intelligent software systems is collectively pushing the boundaries of what is possible, promising a future of mobility that is both efficient and dynamic.